Home Office Pallet-Wood Shelves

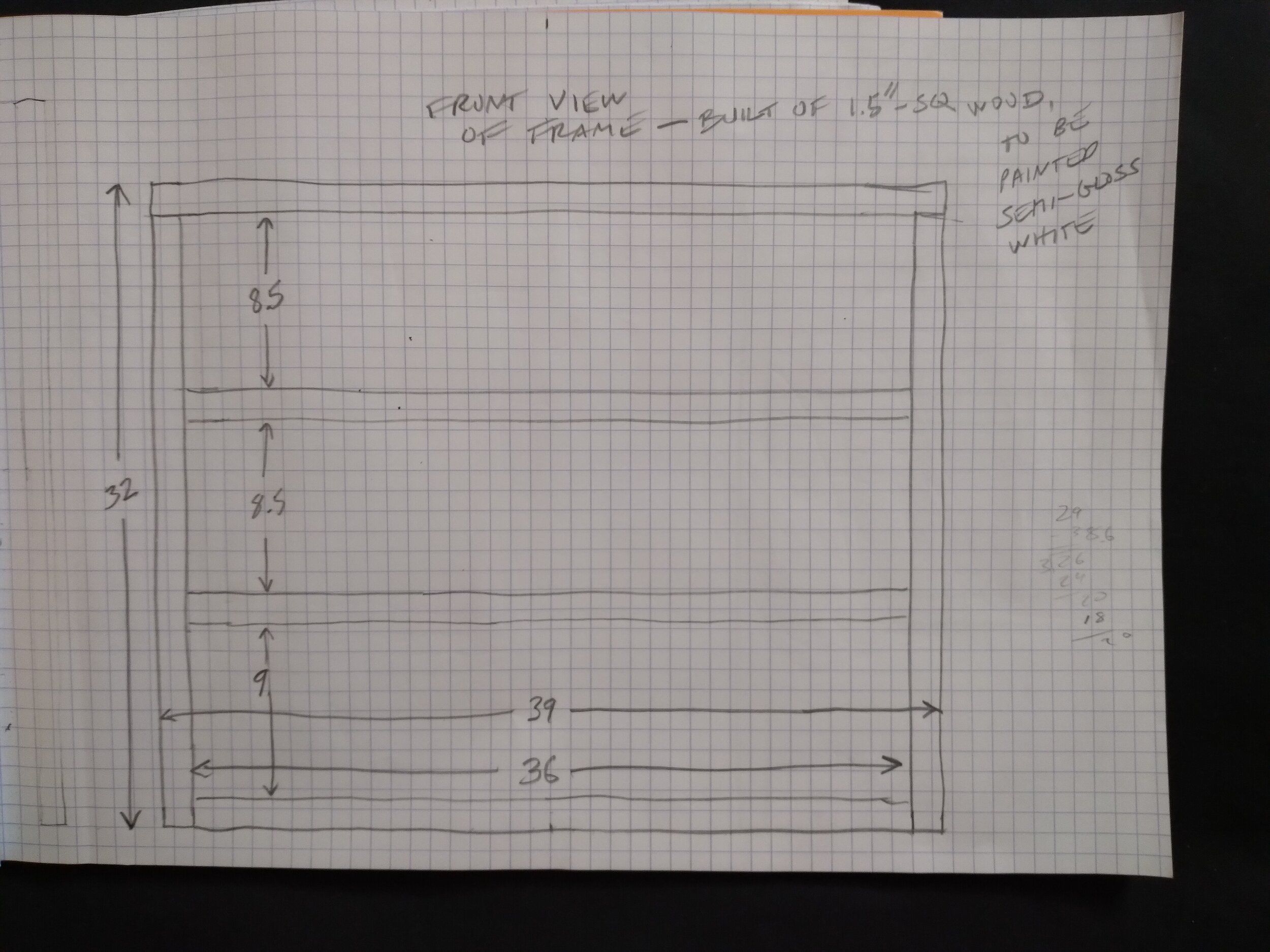

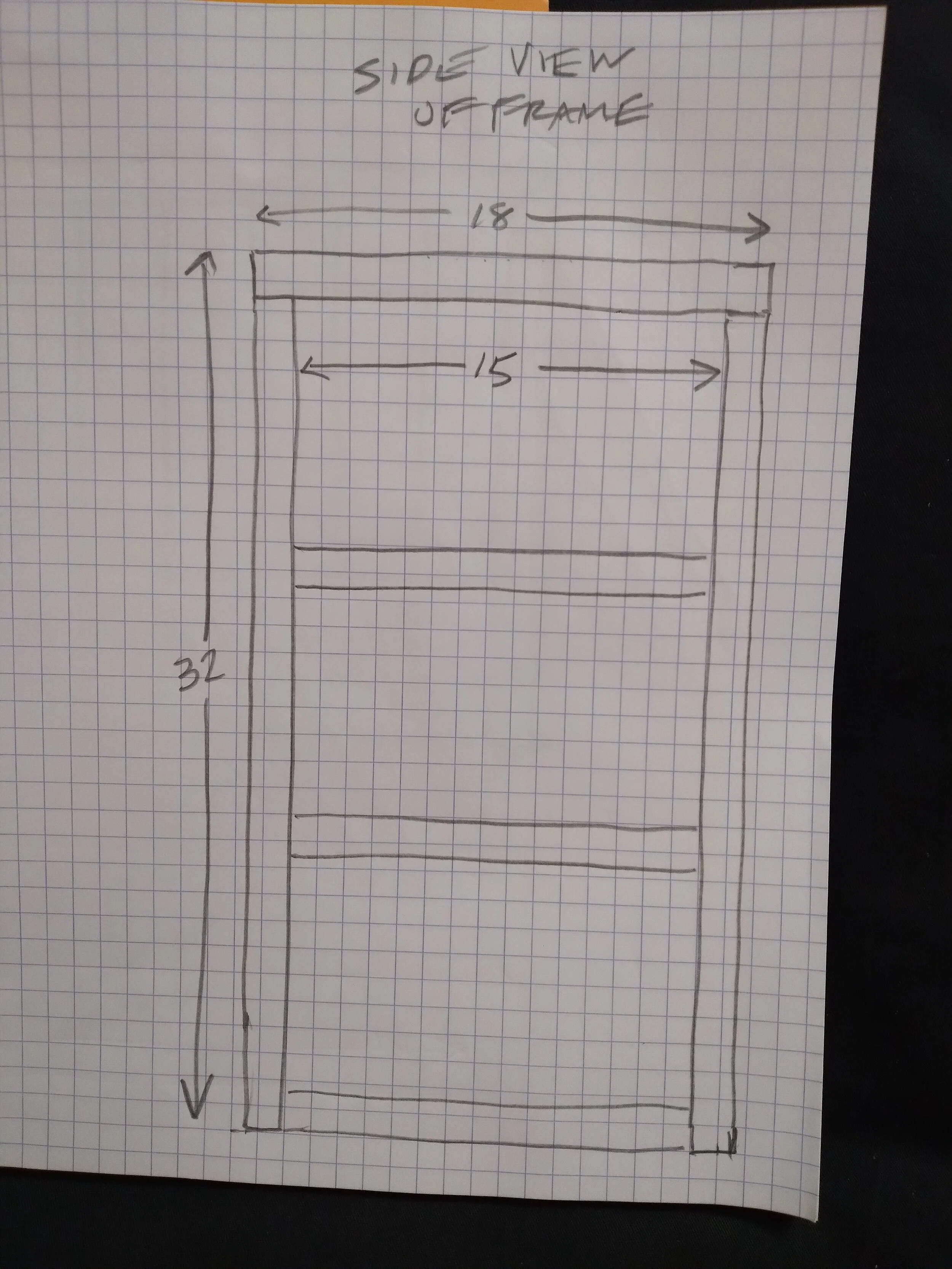

Not for sale; this was a custom project. Dimensions: Width, 39 inches; Height, 33 inches; Depth, 18 inches; Weight, 50 pounds. A former work colleague and his wife asked me to make a set of shelves for her home office, replacing an old metal and glass TV stand. They liked the idea of combining a painted frame with reclaimed pallet wood. To match her desk, she requested white paint. Considering what she wants to store on the unit (such as a printer and supplies) and the floor space available space in her office, together we came up with the basic dimensions and the plan to have four shelves. We also decided together to have the bottom rails of the frame sit directly on the floor, rather than a few inches up, to prevent dust bunnies from getting under a hard-to-clean space. I then came up with detailed plans that I shared with them for approval before I began the work. This included the plan to have the pallet wood planks sit down level with the frame, an approach I had not used before—which made it more complicated, but resulted in a sleeker, more modern (less rustic) set of shelves than if I had just affixed the planks atop the rails, as I had in several other projects.

The Story

The frame is constructed from 1.5-inch-thick square lumber from The Home Depot. The legs and the front and back rails for the bottom three shelves are made from poplar; the other pieces are made from pine. The poplar lumber comes in 3-foot lengths, which meant I didn’t have to cut any of those six rails—saving time—and had to cut only a few inches off for the legs. The pine comes in 8-foot lengths. I set stops on my compound miter saw to ensure all the pieces I cut were the same lengths. I mitered the corners of the top shelf rails and eventually set them on top of the legs for a sleeker look. To enable the planks to sit down in the frame, I used glue and screws to attach ¾-inch square pine lumber along the inside edges of the eight back and front rails. Before assembly, I hand-sanded all the square edges to round/smooth them very slightly. The frame is constructed with simple butt joints, everything held together with glue and 2.5-inch wood screws. I countersunk the screws and then covered the heads with wood putty. I built the short sides first, then joined them together with the long rails, adding the top shelf rails last. After assembly I brushed water on all the surfaces, let it dry, then lightly sanded with 220-grit paper. This step prevents “feathering,” which is the (undesirable) raising of the grain when latex-based paint or water-based poly is applied to raw wood. I finished the frame by brushing on three coats of white semi-gloss paint.

For the shelves themselves, I used reclaimed pallet wood in its original dimensions of roughly 3.25 to 3.5 inches wide and ½-inch thick. I chose wood with generally medium tones, avoiding really dark or light wood. In planning for the shelves to be 18 inches deep including the rails, I knew it would allow me to cut two 15-inch long segments out of each original pallet plank without including any nail heads or nail holes—thus making this piece substantially less rustic than many of my projects that use pallet wood. Each shelf has 10 full-width planks and 1 trimmed down by about half to fill the remaining space. I carefully arranged the individual planks on each shelf to ensure variability in wood grain and tone—no similar pieces are side by side. I numbered all the pieces to ensure they ended up in the right position in the end. Most of the pallet wood I used was already in my stock. I used my belt sander with a rough (80-grit) then fine (120-grit) belt to clean and smooth the 44 individual planks. Then I hand-sanded (150-grit) to slightly round-off the square edges and did a final sanding of the tops and sides with 220-grit paper. I went through the same de-feathering process described above to ensure really smooth top surfaces, but I had to wet and sand many planks three or four times because of the type of wood involved—oak is especially problematic. Then I applied three coats of Minwax water-based clear satin Polycrylic, with a light sanding (220-grit) before the final coat. Finally, I glued the planks into position, three or four at a time, weighting or clamping them down for at least four hours to ensure great adhesion.

I’m quite happy with the final product.

Related Items: Display Shelves Made from Reclaimed Wood, Coffee Table with Ratan Base and Reclaimed Wood Top, “Camouflage” Side Table with Reclaimed Wood Top, Side Table with Two Reclaimed Wood Shelves, End or Side Table Made from Two Bar Stools and Reclaimed Wood.